Scaffold, Tools and Items Monitoring

The UniTech Oakdale plant has begun to offer scaffold, tools and items monitoring and classification services for its customers. The availability of this scaffold monitoring service has generated a significant amount of interest across the UK nuclear industry and the service will fill a gap in the UK market, and hopefully across Europe. Recently, Oakdale provided this service for the first time, to Bradwell nuclear decommissioning plant. Bradwell is located in the Southeast region of the UK.

As the first UniTech UK customer to use the company’s new scaffold, tools and items monitoring service, Bradwell sent eight tonnes of poles and planks to UniTech’s Oakdale plant for monitoring to identify levels of radioactive contamination present.

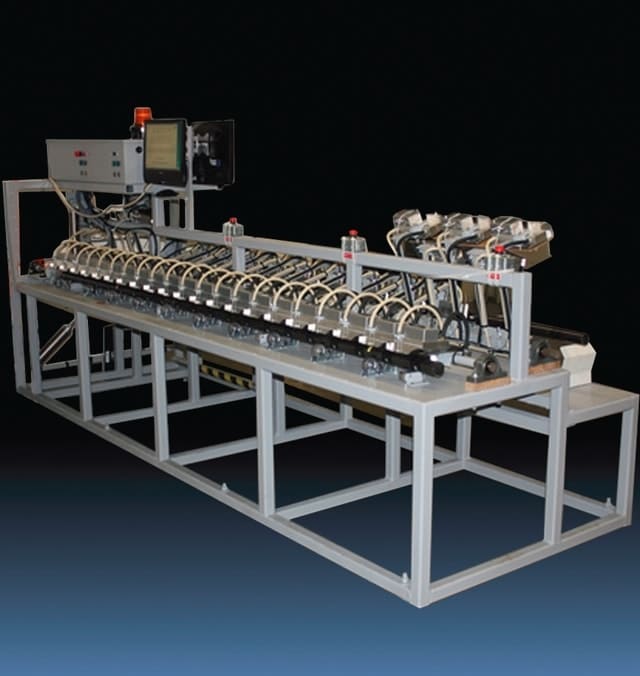

UniTech monitored all of the poles and planks, initially identifying whether any removable contamination was present by wiping them down using UniTech Microfiber wipes, then monitoring. Automated equipment was then used to monitor for fixed contamination down to very low levels.

The monitoring was performed to meet the customer goal of knowing the contamination levels associated with each pole or plank. The items were then returned to Bradwell as per the terms of the contract.

A report was produced and issued to Bradwell to identify levels of contamination on each pole or plank that was sent to Oakdale.

The expanded service will meet a critical need for sites at the end of outages or large projects, and furthers the environmental principle

of reuse. Our growing inventory of instruments at Oakdale enables detection to very low levels of contamination, and we are working closely with UK instrument specialists to ensure the optimised performance of these instruments to meet the requirements and expectations of the UK nuclear industry with a goal to be a market leader in this kind of monitoring service.

To expand its scaffold, tool and equipment monitoring capacity, UniTech is exploring options to enlarge the Oakdale building.

Already, UniTech’s Oakdale facility offers unparalleled monitoring for its customers, providing reliable, repeatable results that these customers value, and thus reducing customers’ liability concerns;

and segregating scaffolding according to radiation levels.